Please contact us if you need further assistance or have any questions.

Suzhou Crown Electronic Technology

Supply Professional Wire Processing Equipment

Tel

+86-19951197968

info@kscrown.com

Suzhou Crown Electronic Technology

Supply Professional Wire Processing Equipment

Tel

+86-19951197968

info@kscrown.com

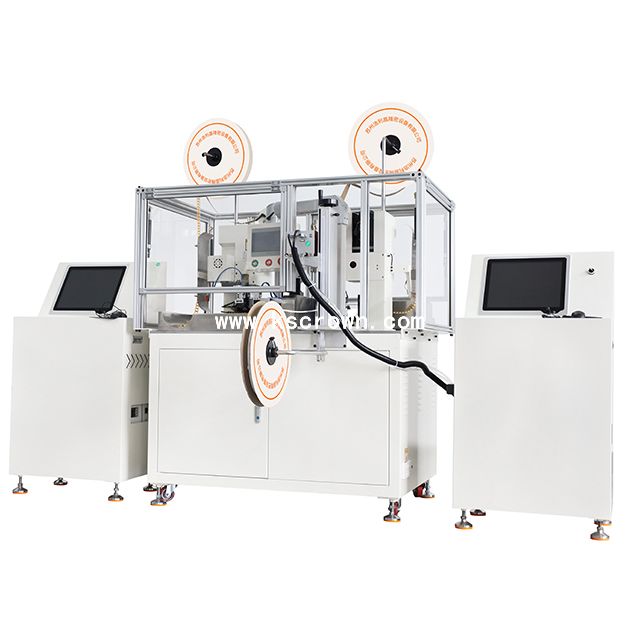

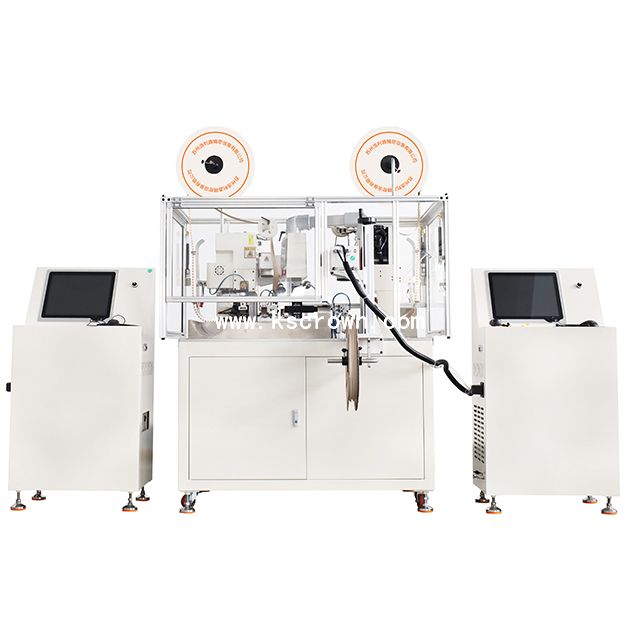

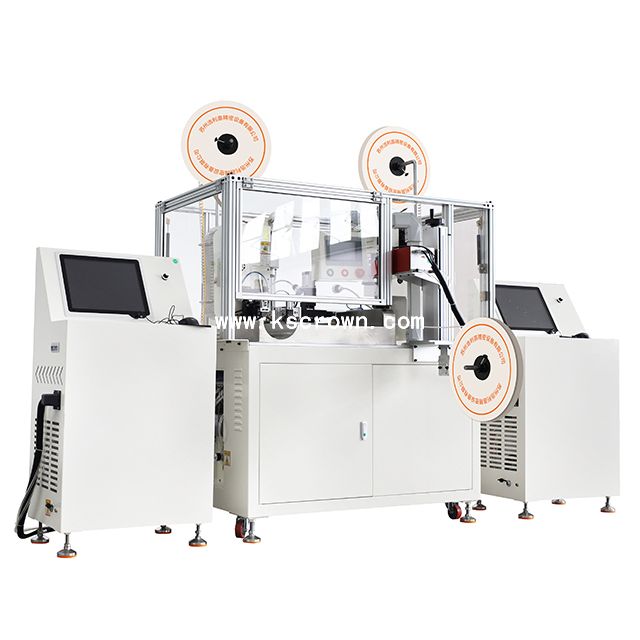

This fully automatic cable double-end crimping and tube insertion marking machine can process wire cutting, wire stripping, laser printing, tube insertion and terminal crimping at both ends in one pass.

|

Model:

|

|

○ Using silent electronic clutch terminal machine

○ 7-Inch digital and graphical control touch screen interface, more intuitive.

○ The wire feeding mechanism is improved, with ultra-low noise.

○ Reduce the use of solenoid valves

○ Using the most advanced European-style right-angle casting terminal machine at present, the horizontal and straight applicators can be quickly replaced, and the body structure is exquisite. The common OTP/2000 type horizontal and direct feeding applicators on the market can be applied.

| Model | WL-SYSC02 |

| Maximum production capacity | 1400 pieces/hour (length=300MM) |

| Wire size | AWG1007 12#-24# |

| Cutting length | 60mm-3000mm (800MM or more need to be equipped with conveyor belt) |

| Cutting accuracy | 0.5MM + cutting length × 0.2% or less |

| Stripping length | R<10MM L<14MM (other stripping lengths need to be customized) |

| Crimping capacity | Standard 2T |

| Power | 0.75KW |

| Power supply | AC220V 50/60 HZ 20A single phase |

| Compressed air | 0.5MPA (5kgf/cm) |

| Control mode | MSP430E micro-controller, 165NA/MIPS working mode, 5US standby wake-up, high-speed operation |

| Detection device |

1. Detection of bad crimping 2. Terminal missing detection 3. Wire missing and knot detection 4. Machine anomaly detection 5. Total amount detection |

| Optional accessories |

1. Cassette applicator and blade |

| Dimensions | 1330L*930W *1600H(MM) |

| Weight | 640KG |