Please contact us if you need further assistance or have any questions.

Suzhou Crown Electronic Technology

Supply Professional Wire Processing Equipment

Tel

+86-19951197968

info@kscrown.com

Suzhou Crown Electronic Technology

Supply Professional Wire Processing Equipment

Tel

+86-19951197968

info@kscrown.com

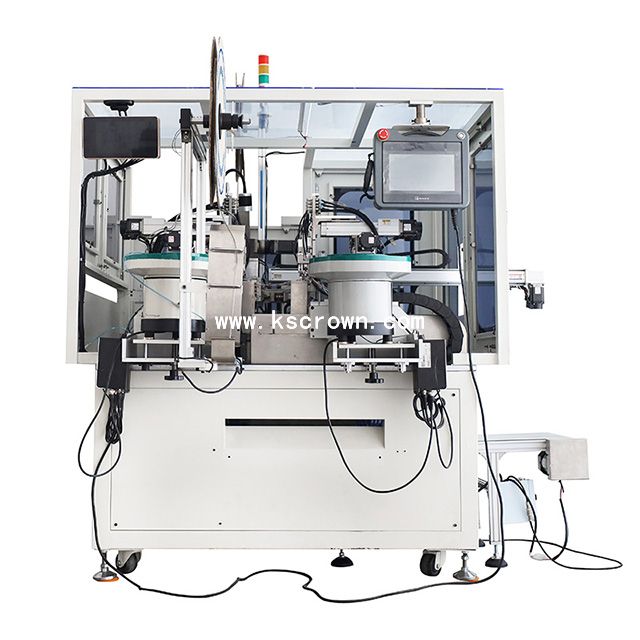

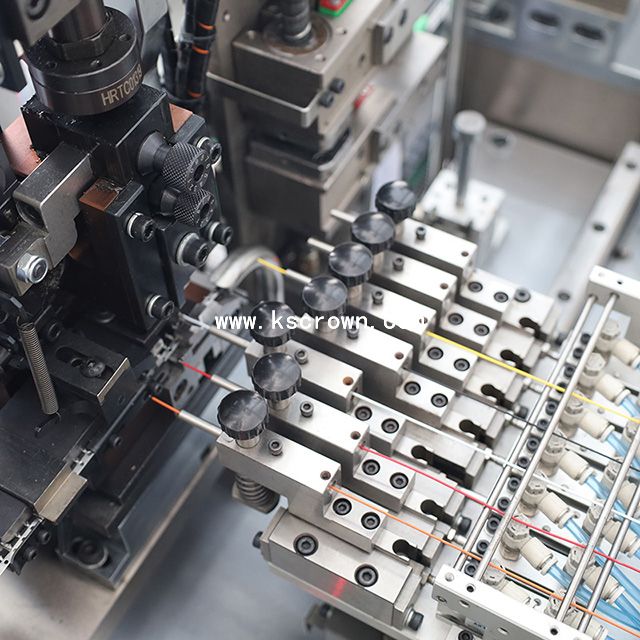

This is a fully automatic cable double-end connector housing inserting machine. It is able to process cable cutting, stripping, and both ends terminal crimping and housing connector insertion.

|

Model:

|

|

○ Full servo motor control, high precision

○ The plastic housing can be inserted in staggered positions.

○ Produce products with different wire lengths

○ Full computer touch screen control, convenient and quick debugging

○ Detection device: wire absence detection, terminal absence detection, crimping force detection CFM, terminal size detection (visual CCD), plastic housing pullback detection

○ Arbitrary cutting length (within the stroke range)

| Model | WL-STCJK09 |

| Applicable wire | AWG#32-AWG#16 |

| Function |

Both ends terminal crimping & connector housing inserting, and the length of the wire can be unequal; Optional 90-degree flip plastic housing inserting, staggered positions housing inserting, jump pin plastic housing inserting; It can have one housing at one end and multiple housing connectors at the other end (the same type of housing connector, different number of pins); double-layer plastic housing shells can be inserted; The plastic housing shells at both ends can be on the same side, on the front and back sides. |

| Capacity |

AWG#32-AWG#30 about 1300 holes/hour (wire length within 100MM) AWG#28-AWG#20 about 1600 holes/hour (wire length within 100MM) |

| Cutting length | standard 80MM-500MM (special requirements need to be customized: shortest 80MM, longest 450MM ) |

| Cutting accuracy | cutting length is less than 100MM, deviation is less than 0.3MM (cutting length x0.002); cutting length is greater than 100MM, deviation is less than 0.3MM+ (cutting length x0.002). |

| Stripping length | front end: 1.0-6.0MM (half stripping length 2.0-6.0MM), rear end: 1.0-8.0MM (half stripping length 2.0-8.0MM) |

| Applicable applicator | horizontal feed applicator |

| Crimping machine | 2.0T crimping machine |

| Control mode | 10-inch touch screen, intelligent PLC control |

| Detection device | wire absence detection, terminal absence detection, crimping force detection CFM, terminal size detection (visual CCD), plastic housing pullback detection |

| Power supply | single phase: AC210V-AC230V 20/60HZ 10A |

| Compressed air | 0.6-0.8MPa (need to use clean and dry air source) |

| Dimensions | 1800Wx1600Lx1750H(mm) |

| Weight | about 1000KG |