Please contact us if you need further assistance or have any questions.

Suzhou Crown Electronic Technology

Supply Professional Wire Processing Equipment

Tel

+86-19951197968

info@kscrown.com

Suzhou Crown Electronic Technology

Supply Professional Wire Processing Equipment

Tel

+86-19951197968

info@kscrown.com

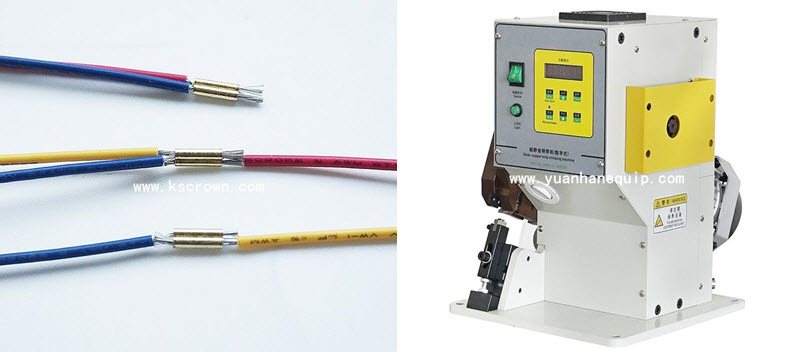

The wire copper band splicing crimping machine provides an advanced method for producing low-cost, high-reliability connections. The system is comprised of a semi-automatic machine and a reel of continuous splice copper band material, and it's available with a range of crimping die types and splice copper band sizes to meet a variety of production requirements.

Model: WL-3T

Features

○ This machine is equipped with 750W motor and RV63 reducer, and it has a large crimping force because of the large torque with a 40 percent increase over the traditional machines.

○ The three axles through-type spindle mounting method, front and back supporting, concentric axles without gap, keeps the crimping force much firmer.

○ The stepping motor drives the feeding, digitizes the length, the adjustment is simple and fast, and the feeding is stable.

○ The diameters of main axle and eccentric shaft are expanded to lead the main axle to have better intensity and be more durable.

○ The optimized box structure with the machine head in the box, has stronger bearing strength than the traditional machines in which four screws are used to connect the machine head to the middle base.

○ Optimize the operating height, lower the operating height to the height of the fist, and support the bottom of the machine to reduce the operating fatigue during operation.

Contact us: info@kscrown.com

Operation video of the splicing crimping machine

Technical data

| Model | WL-3T |

| Voltage | AC220/60HZ |

| Motor Power | 750W/RV63/1;15 |

| Crimping Force | 2.5T |

| Copper Strip Feeding Mode | Motor Drive / Step Feeding |

| Maximum Copper Strip Length | 60MM/Maximum Copper Strip Length 22MM |

| Maximum Copper Strip Width | 6MM |

| Maximum Crimping Width | 6.5MM |

| Maximum Crimping Diameter | 6mm2 X 2 |

| Operation Mode | Pedal Switch / Single Action |

| Dimensions | 300 x 300 x 400 (MM) |