Please contact us if you need further assistance or have any questions.

Suzhou Crown Electronic Technology

Supply Professional Wire Processing Equipment

Tel

+86-19951197968

info@kscrown.com

Suzhou Crown Electronic Technology

Supply Professional Wire Processing Equipment

Tel

+86-19951197968

info@kscrown.com

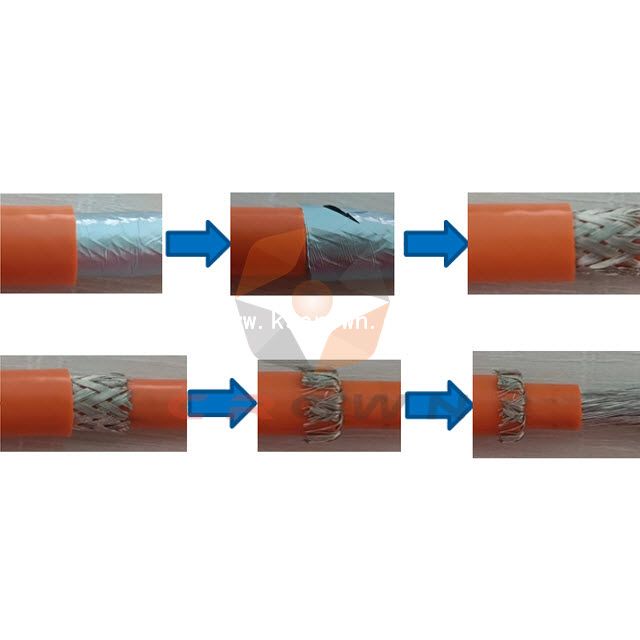

The high voltage cable processing machine is a cutting-edge piece of equipment designed to streamline and enhance the processing of high-voltage cables. This advanced machine offers a range of features and capabilities that ensure efficient and precise cable processing, making it an indispensable tool for industries dealing with high-voltage applications. It can complete operations such as stripping off the outer jacket of high-voltage cables, cutting off aluminum foil, cutting off braided shielding, stripping off inner insulation layer, and turning over braided shielding at one time.

|

Model:

|

|

○ Functions: stripping off the outer jacket of high-voltage cables, cutting off aluminum foil, cutting off braided shielding, stripping off inner insulation layer, and turning over braided shielding

○ Reserve Multiple Interfaces: A variety of interfaces are reserved to expand functions such as scanning, printing, and connecting to MES.

○ Enhanced Efficiency: Our High-Voltage Cable Processing Machine is equipped with state-of-the-art technology that significantly improves processing speed and accuracy. This allows for faster production cycles and increased productivity, ultimately saving valuable time and resources.

○ Precision Cutting: With its advanced cutting mechanism, this machine ensures clean and precise cuts on high-voltage cables of various sizes. The accuracy of the cuts minimizes waste and guarantees optimal cable performance, reducing the need for rework and enhancing overall product quality.

○ Versatility: The High-Voltage Cable Processing Machine is designed to handle a wide range of cable types, including single-core, multi-core, and shielded cables. Its adaptability makes it suitable for diverse applications, catering to the specific needs of different industries.

○ User-Friendly Interface: Our machine features an intuitive and user-friendly interface, making it easy for operators to navigate and control the processing parameters. This simplifies the operation process, reduces the learning curve, and ensures consistent and reliable results.

○ Safety Measures: Safety is of utmost importance when dealing with high-voltage cables. Our machine incorporates robust safety features, including emergency stop buttons, protective enclosures, and voltage monitoring systems. These measures guarantee the well-being of operators and prevent accidents, ensuring a secure working environment.

○ Durability and Reliability: Built with high-quality materials and components, the High-Voltage Cable Processing Machine is designed to withstand demanding industrial environments. Its robust construction ensures long-lasting performance, minimizing downtime and maintenance costs.

|

Model |

WL-GY04 |

|

Air supply |

0.5-0.7Mpa |

|

Voltage |

380V/50Hz |

|

Power |

3.5KW |

|

Wire cross sections |

2.5-150mm² |

|

Dimensions |

1020(L)*1062(W)*1720(H) |

|

Weight |

300Kg |

|

Function |

stripping off the outer jacket of high-voltage cables, cutting off aluminum foil, cutting off braided shielding, stripping off inner insulation layer, and turning over braided shielding |

|

Qualification rate |

no less than 99% |

|

Cycletime |

up to 15S (Different products have differences. ) |

|

CCD detection |

Use CCD cameras to detect defective products, save pictures and upload them to the MES system. |

|

A variety of interfaces are reserved to expand functions such as scanning, printing, and connecting to MES. |

|