Suzhou Crown Electronic Technology

Supply Professional Wire Processing Equipment

Tel

+86-19951197968

info@kscrown.com

Suzhou Crown Electronic Technology

Supply Professional Wire Processing Equipment

Tel

+86-19951197968

info@kscrown.com

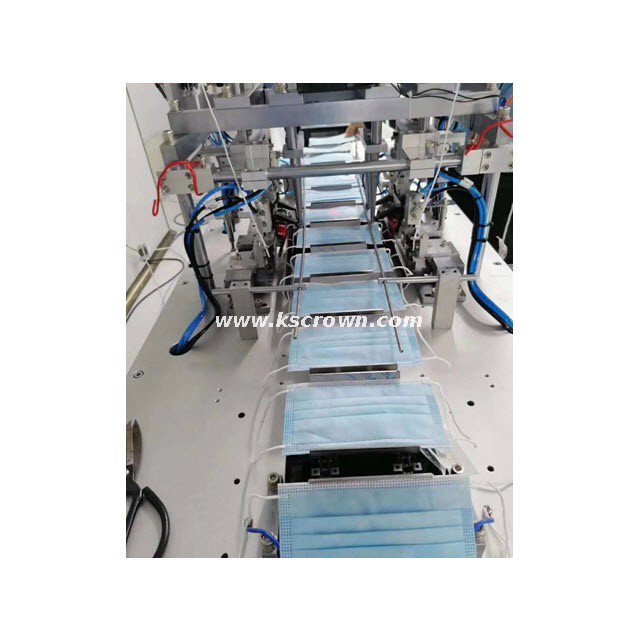

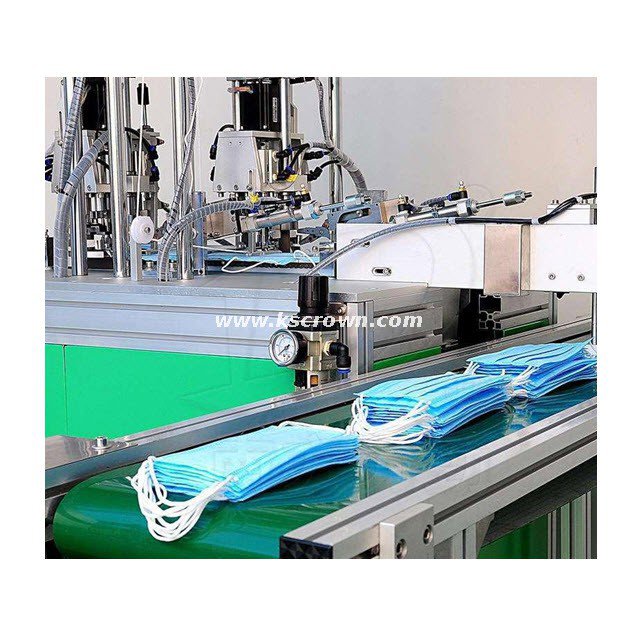

This production line realizes the fully automated production of flat masks, mainly including coil material feeding, folding and pressing, nose bridge tendon material feeding, mask forming, mask cutting, ear band feeding and welding, finished product unloading and other processes, completing the whole production process from coil material to finished product of mask. The produced masks are comfortable to wear, non-stressed, and have a good filtering effect, which fits the face shape of people and can be used in medical, electronics, mining, construction and other industries.

|

Model:

|

|

High-speed production, daily production of 100,000 masks, 99% pass rate (24-hour production);

Modular and humanized design, safe and easy operation, convenient maintenance, one person can operate.

If the equipment is abnormal or the material is cut off, it will automatically alarm and the screen will guide you to deal with the abnormality quickly.

| Model | WL-210 |

| Product specifications | 175 mm*95mm |

| Product structure | Left & right elastic ear band + outer non-woven fabric + nose bridge bar + melt blown fabric + inner non-woven fabric |

| Design speed | 120 pieces/min |

| Production speed | 100 tablets per minute |

| Installed capacity | about 10 KW (including air compressor power) |

| Compressed air | 0.6~0.8 Mpa, 1.0 m3/min |

| Defective rate | ≤1%(excluding defective products due to glue sprayers and material joints) |

| Boot rate | ≥85% |

| Machine color | sheet metal warm ash 1 C, aluminum profile primary color |

| Weight | about 5T |