Please contact us if you need further assistance or have any questions.

Suzhou Crown Electronic Technology

Supply Professional Wire Processing Equipment

Tel

+86-19951197968

info@kscrown.com

Suzhou Crown Electronic Technology

Supply Professional Wire Processing Equipment

Tel

+86-19951197968

info@kscrown.com

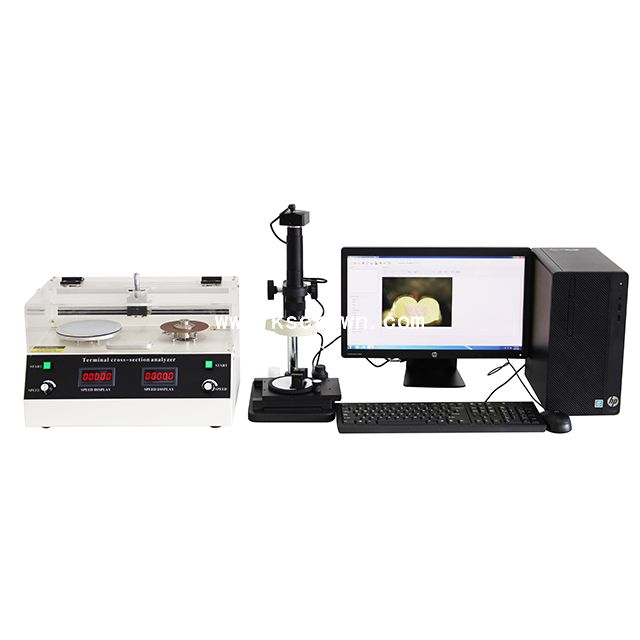

The terminal cross-section analyzer is designed to detect the quality of crimping terminal. It includes the following modules: terminal fixture, cutting and grinding, corrosion cleaning, cross-section image acquisition, measurement and data analysis, generate data reports. It only takes about 5 minutes to complete the cross-setion analysis of a terminal.

|

Model:

|

|

○ Mainly used for cross section testing of terminal after crimping

○ Exquisite and portable in structure design, and easy to operate

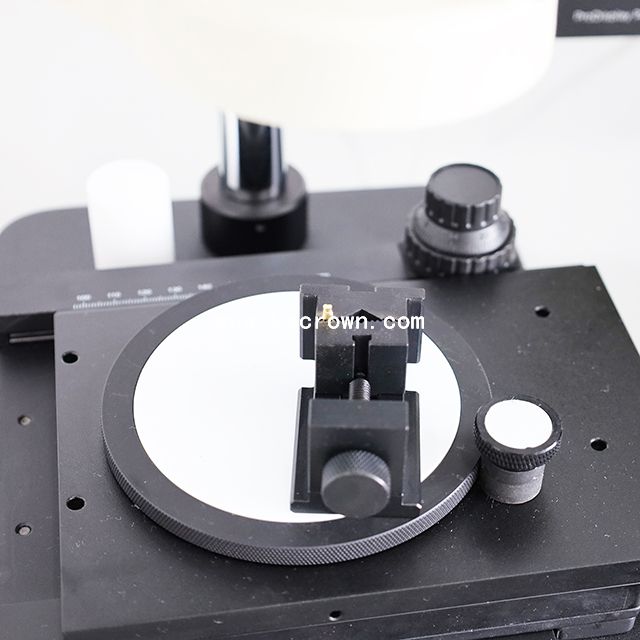

○ High quality optical instrument with low distortion and image capture module

○ Optical instrument with safety protection device, and easy for transportation

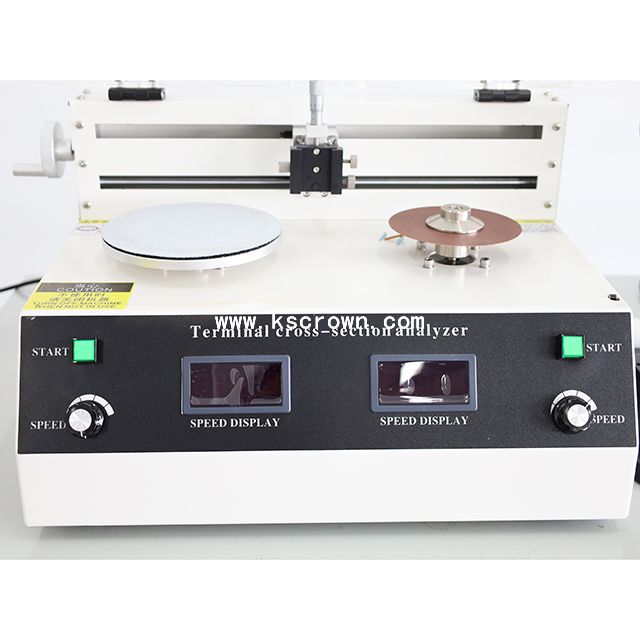

○ Automatic cutting module, with high-speed grinding module with fine adjustment

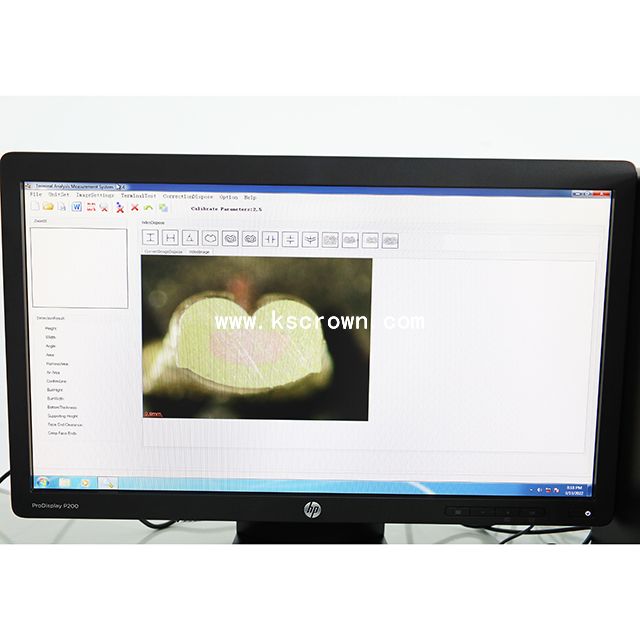

○ Testing result is automatically generated from the relevant software

| Model | WL-SE3 |

| Terminal cross section analysis | Japan imported segmentless zoom optical system |

| Total video magnification | 30~312X |

| Applivable wire range | 0.01~33mm2 (Max. 120mm2) |

| Power supply | 100~240VAC, 50/60Hz |

| Imaging system | Japanese industrial HD video system 5 million |

| Cut blade specifications | Φ150x0.5mm(Imported from Germany, delicate and durable) |

| Abrasive sandpaper | 1200# |

| Standard fixture | 0.01~33mm2 |

| Professional high-precision reference ruler | 0.01/10mm |

| Terminal corrosion | Liquid cleaning (5S completed) |

| Lighting source | All white adjustable LED lighting device |

| Dimensions | W500 x D350 x H350 |

| Feature |

Precision integrated automatic cutting and grinding equipment, German motor 0~4000rpm stepless speed regulation, professional terminal cross section analysis software Section-MS with encryption lock and CD |