Suzhou Crown Electronic Technology

Supply Professional Wire Processing Equipment

Tel

+86-19951197968

info@kscrown.com

Suzhou Crown Electronic Technology

Supply Professional Wire Processing Equipment

Tel

+86-19951197968

info@kscrown.com

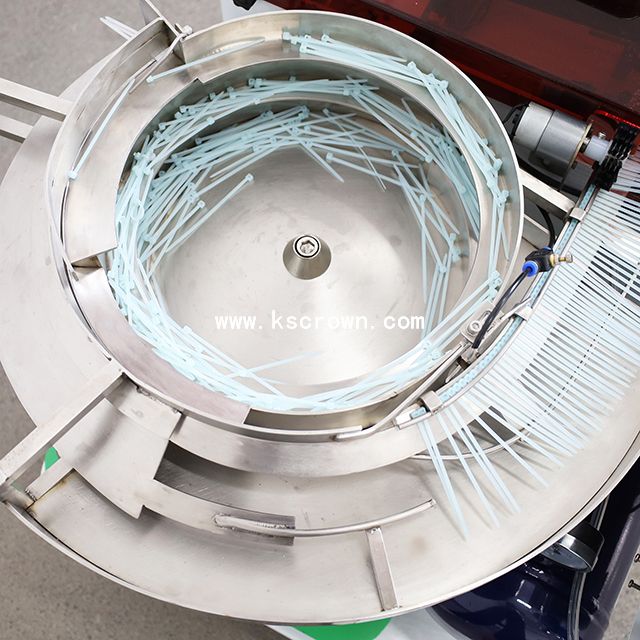

This automatic bundling machine is specially used for motor stator coil tying. It can also be used for bundling other products. It’s convenient and easy to operate.

|

Model:

|

|

○ Put disordered bulk material ties into the vibrating plate at will, and the ties will be transfered to the gun head through the pipeline.

○ Step on the pedal to automatically complete all actions such as feeding, reeling, tightening, cutting, and discarding waste.

○ In 0.8 seconds, complete all actions such as feeding, reeling, tightening, cutting, and discarding waste, including auxiliary time. The whole cycle is about 2 seconds.

○ Waste materials are automatically collected in the waste box through a special recycling system (optional configuration).

○ The binding force or tightness can be adjusted.

○ PLC control system, touch screen display, simple and clear operation.

○ It can be used with manipulators to realize automatic cable tie in the automatic production line, or it can be fixed on the table as a desktop cable tie machine.

○ The whole machine has an automatic detection function to monitor each operation. Once an abnormality is found, the machine will immediately stop its action and give an alarm

○ Automatic detection of material blocking. If material blocking is found, the machine will immediately stop and give an alarm and a key clear function

○ To deal with different temperature differences in the area, the equipment is equipped with a temperature control system that can control the temperature of the cable tie.

| Model | WL-PA25100M |

| Cable tie specifications | 2.5*100 mm (specific to the actual product) |

| Banding efficiency | 0.8 S/PCS |

| Applicable stator | 54#, 60#, 70#, etc. (subject to the actual product) |

| Binding range | subject to the actual product or customized |

| Vibration plate feeding quantity | about 300 PCS/time |

| Host size | L735*W825*H670 mm |

| Cable tie table size | L365*W300*H350 mm |

| Applicable air pressure | 5~6 Kg/cm2 |

| Applicable power supply | 220V 50/60HZ |

| Whole machine weight | about 150Kg (with casters, can be easily weighed) |