Please contact us if you need further assistance or have any questions.

Suzhou Crown Electronic Technology

Supply Professional Wire Processing Equipment

Tel

+86-512-5775-0238

info@kscrown.com

Suzhou Crown Electronic Technology

Supply Professional Wire Processing Equipment

Tel

+86-512-5775-0238

info@kscrown.com

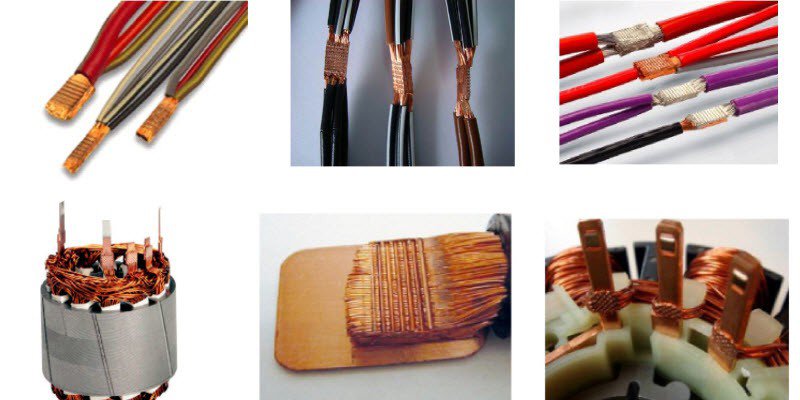

The ultrasonic metal welding machine uses the ultrasonic high-frequency vibration friction principle to convert the energy of the ultrasonic vibration into friction energy and transfer it to the metal surface to be welded. When friction generates heat and applies pressure thereto, the metal structure molecules are fully activated, thereby forming a fusion between the molecular layers. It is widely used in battery and hardware industry.

Machine Highlights

Touch screen display, continuous power adjustment, simple operation, stable and reliable operation.

Strong welding and good consistency.

Easy to operate, built-in electronic protection circuit, safe to use, suitable for metal welding, single or multi-point welding of non-ferrous metals.

Widely used in battery and hardware industry.

Frequency automatic tracking and tuning, real-time display of current frequency, no need for manual tuning, automatic tracking of optimal working conditions.

It has double protection function of transducer failure, overheating and load overcurrent.

The output power is automatically adjusted according to the load.

Adaptive various parameter transducers.

The working mode and parameters are all digitally freely set.

Frequency automatic scanning, fully automatic tracking, great working bandwidth.

Four modes: time mode, continuous mode, energy mode and broken mode.

Metal welding features:

> Flux and external heating are not required, no deformation due to heat, no residual stress, and pre-weld treatment requirements for the surface of the weldment are not high. Not only the same kind of metal, but also can be welded between different metals. Sheets or filaments can be welded to the slab.

> Ultrasonic welding of good electrical conductors is much less energy than current welding and is commonly used for the soldering of leads for transistors or integrated circuits. When used for sealing welding of drugs and explosive materials, it can avoid the general welding of contaminated drugs due to dissolved objects, and will not explode due to heat.

Send email to info@kscrown.com for a quotation

Operation video of the ultrsonic metal welding machine

Technical Data

| Model | WL-3500 |

| Power | 2600-3300W (30%-100% adjustable) |

| Frequency | 20K automatic chasing frequency |

| Weight | 45KG |

| Welding time | adjustable |

| Welding area | depending on the product |

| Power supply | AC220V 1P 10A |