Suzhou Crown Electronic Technology

Supply Professional Wire Processing Equipment

Tel

+86-512-5775-0238

info@kscrown.com

Suzhou Crown Electronic Technology

Supply Professional Wire Processing Equipment

Tel

+86-512-5775-0238

info@kscrown.com

The intelligent temperature-adjusting double-sided heat-shrinkable tube heating machine is suitable for heating shrinkage of heat-shrinkable tube in wire harness processing enterprise. It can adjust the temperature according to the requirements of the production process, and the contraction time is short. It can shrink any length, and work continuously for 24 hours without interruption. There are omnidirectional reflective thermal materials, so that the heat shrinkable tube is heated evenly.

|

Model:

|

|

Equipment composition

Equipment bracket + conveying system + heating system + cooling system + control system

Heat insulation design of heating zone

The shell of the heating area is designed with double layer heat insulation, which makes the inside and outside temperature separate, that is to save energy and protect the working environment.

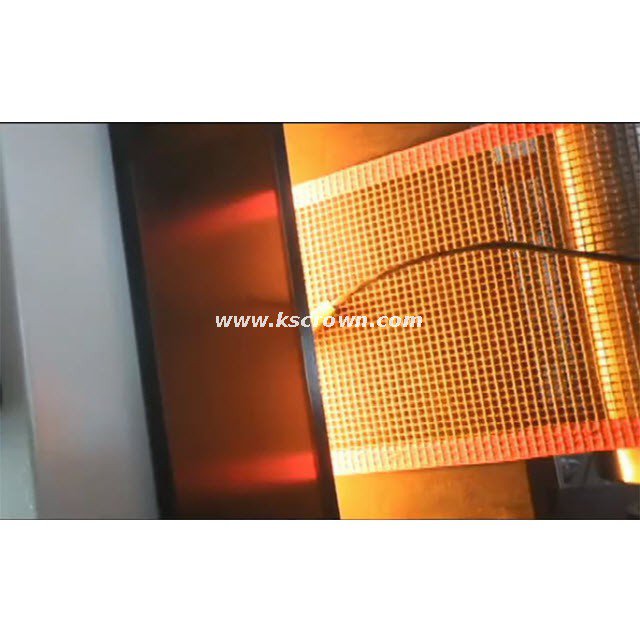

Omni-directional heat reflecting inner wall

The heat reflecting inner wall in the heating box ensures the uniform heating effect of the heating.

Adjustable import and export height

The conveyor belt heating box is completely closed, the input and output end of the heating box has a sliding door that can rise and fall, effectively prevent the heat source from leakage, protect the working environment, energy conservation, and increase the machine's ability to use one machine in many different jobs.

Adjustable infrared heating pipe height

The infrared heating tube can adjust the height quickly. Ensure repeatability of distance between light source and conveyor belt.

Detachable brackets

The bracket of the equipment can be disassembled freely, which increases the adaptability and mobility of the equipment.

Cooling system

The outlet is equipped with a cooling fan to cool the heated shrink tube

| Model | WL650A-2 | |

| Size | Overall machine size (L×W×H) | 1800×750×1280mm (Containing the air duct and motor) |

| Conveyor (L×W×H) | 1800×650×1150mm | |

| Heating area (L×W) | 1000×650mm | |

| Outer packing size | 1890×950×730 | |

| Belt width | 400mm | |

| Maximum transmission width | 450mm | |

| Maximum transmission height | 100mm (Adjustable) | |

| Conveyor belt | Material quality | Teflon |

| Speed | 1~5m/min | |

| The power of motor | 90W (Stepless speed regulation) | |

| Heating pipe | Heating pipe name | Infrared heating tube |

| Heating pipe power | 500W*16 | |

| Power Supply | Power demand | 380V |

| Power | 8400W | |