Suzhou Crown Electronic Technology

Supply Professional Wire Processing Equipment

Tel

+86-512-5775-0238

info@kscrown.com

Suzhou Crown Electronic Technology

Supply Professional Wire Processing Equipment

Tel

+86-512-5775-0238

info@kscrown.com

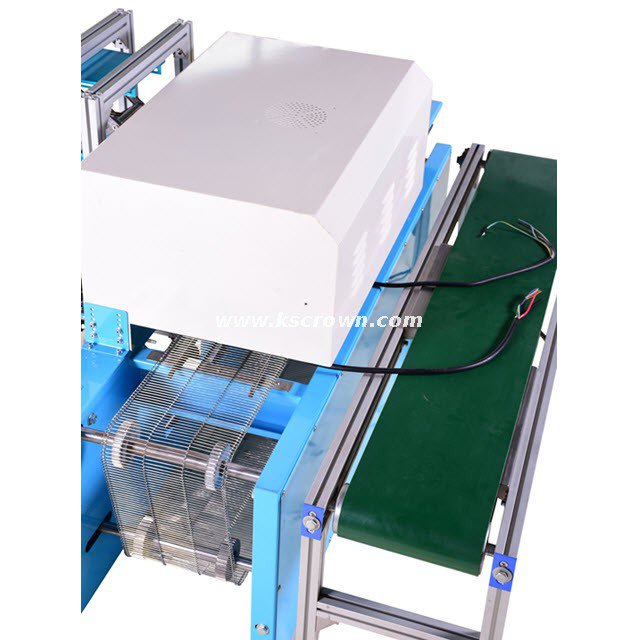

WL200B-2F-380 is a conveyor belt heat shrinkable tube heating machine, which is designed for mass production. The heating machine and the conveyer are used together to realize the precise heating of the heat shrinkable tube without damaging the wire. By manually adjusting the speed, the speed of the conveyor belt is kept uniform. The vertical distance and the parallel distance of the heating port to the conveyor belt can be adjusted, and the heat shrinkable tube of different size components can be heated. It is especially suitable for heating high temperature Teflon heat shrinkable tubes or large diameter and long heat shrinkable tubes.

|

Model:

|

|

One side or double side heating is optional

According to the heating requirements of the heat shrinkable tube, it is free to choose one side or two side heating.

The heating zone width, heating distance and left and right position can be adjusted.Accurate heating does not hurt the wire

The width of the heating zone and left and right position can be adjusted by the user according to the size of the heat shrinkable tube, save energy as much as possible and ensure the wire do not be hurt.

Heat insulation of heating machine

Double insulation, strong machine shell makes the machine safe and reliable, and can work in high temperature for a long time.

The temperature regulation of the heating machine (room temperature ~460℃) is precisely controlled by±1℃

The outlet is equipped with a temperature sensor, which can adjust the temperature according to the needs.The precision of temperature control is 1℃.

Term ordering detection function

This machine control system is equipped with motor item ordering sequence detection function.If the item ordering error,the item ordering warning indicator lights up.

Fan delay function

In order to protect the heating core and prolong the service life of the heating core, the machine has a time delay function of downtime and blow drying. After the machine stops working, the hair dryer will blow off for a minute before it can be shut down.

High heat exchange efficiency

Ingenious design of wind tunnel let the air uniform through the inside and outside of the helical heating wire.Heat exchange near 100%,the loss of wind pressure is less.The heating core of the heater is designed to use the lower surface power density, and the heating temperature in the unit area is low, so the electric heat wire has a long service life.

Air flow regulating valve

The air inlet of the blower is equipped with a manual air volume regulating valve, and the air volume can be adjusted according to the needs.

Security

It has overheating overload protection, power cut protection device, emergency stop switch, phase sequence protection, fully guarantee the safety of the equipment,do not produce exhaust gas, and meet the environmental protection,can keep operating 24 hours a day without stopping all year round.

Selection of assembly auxiliary conveyor

This machine is work in with auxiliary conveyors, and can be applied to heat shrinkable tubes with arbitrary specifications.

| Model | WL200B-2F-380 | |

| Size | Conveyor (L x W x H) | 1250*320*360mm selective assembling |

| Heating machine (L x W x H) | See picture | |

| Maximum wire harness diameter | 20mm | |

| Maximum heating width | <90mm | |

| Heating area | 400mm | |

| Cooling zone | 200mm | |

| Maximum transmission width | 250mm | |

| Maximum transmission height | <60mm | |

| Conveyor belt | Texture of material | Stainless steel |

| Speed | 1~3m/min | |

| The power of the motor | 25W(Stepless speed regulation) | |

| Heating | Heating mode | Hot air |

| Heating pipe power | 6000W, 2 sets | |

| Power supply for heating machine | Power demand | 380V three phase four wire 50HZ |

| Power | 12.3KW | |