Suzhou Crown Electronic Technology

Supply Professional Wire Processing Equipment

Tel

+86-512-5775-0238

info@kscrown.com

Suzhou Crown Electronic Technology

Supply Professional Wire Processing Equipment

Tel

+86-512-5775-0238

info@kscrown.com

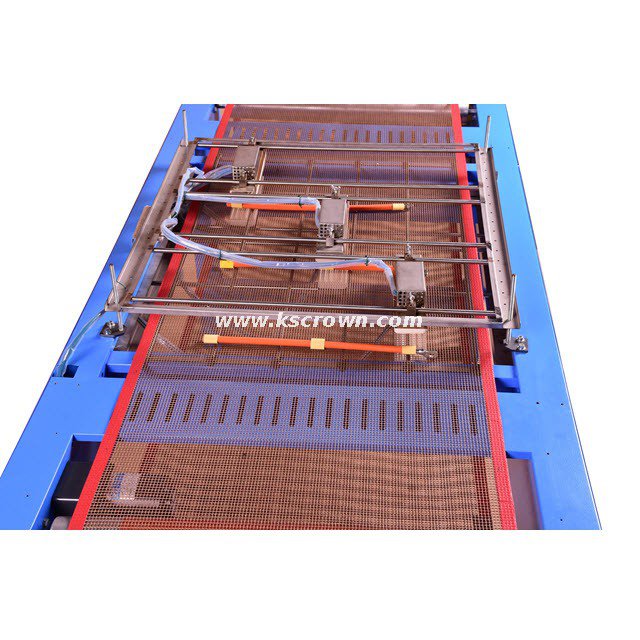

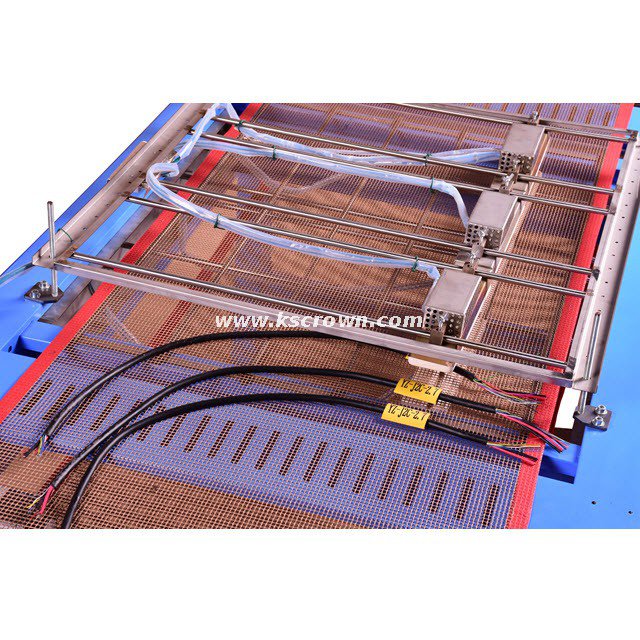

The double-sided shrinkable tube heat shrinking machine comes with Intelligent temperature control, is suitable for heating & shrinking heat-shrinkable tube in wire harness processing enterprise. It can adjust the temperature according to the requirements of the production process, and the contraction time is short. It can shrink any length, and work continuously for 24 hours without interruption. There are omnidirectional reflective thermal materials, so that the heat shrinkable tube is heated evenly.

|

Model:

|

|

Equipment composition

Conveying system + heating system + cooling system + control system

Heat insulation design

The heating zone shell is double-designed to isolate the internal and external temperature, which saves energy and protects the working environment.

Conveyor system

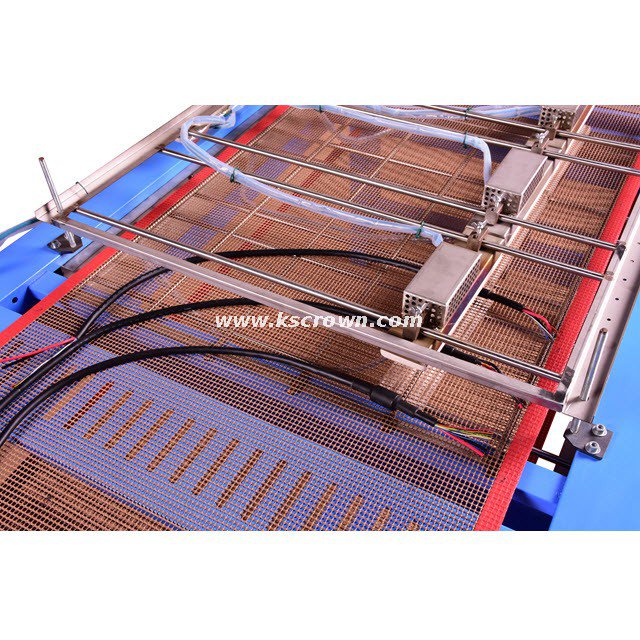

The conveying speed is controlled by a speed-regulating motor, which can smoothly adjust the speed and adjust the length of the heated wire harness through the heating zone.

Adjustable heating plate height

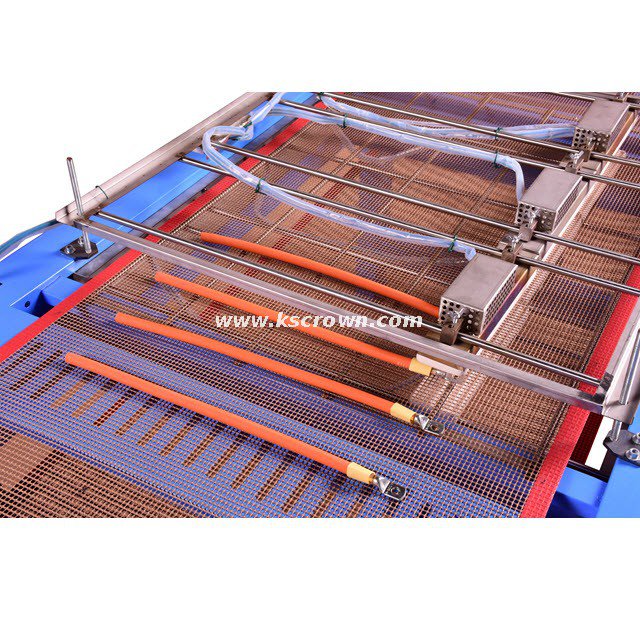

Can process products with multi-diameter

Flexible heating zone design

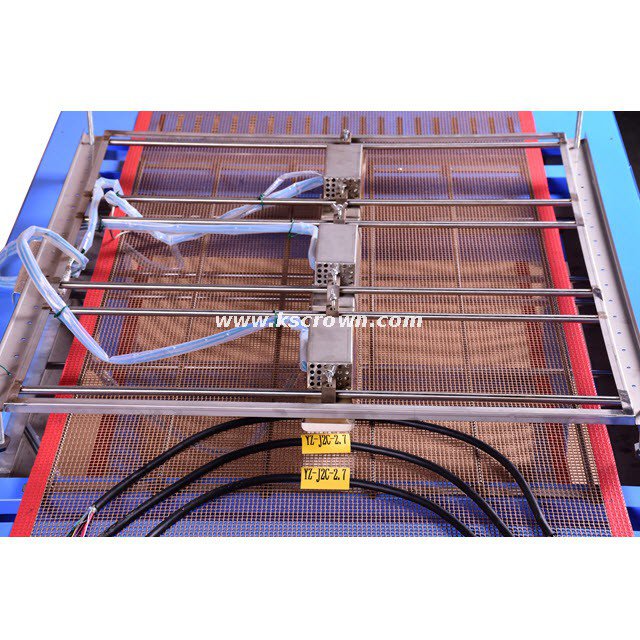

The heating zone adopts upper and lower double-sided design, and uses a windless heating plate, which is energy-saving and can effectively improve the working environment. Ceramic heating plates allow for quick height adjustment. In single-sided, double-sided and single-row, double-row heating switching, it can be adjusted between 3, 6, 9, 12 heating plates to meet different wire bundle heat shrink requirements.

Removable bracket

The stand of the device can be freely disassembled, increasing the adaptability and mobility of the device.

Cooling system

The outlet is equipped with a cooling fan to cool the heated heat-shrinkable tube.

Intelligent control system

Easy to learn temperature control settings

The temperature control system is set up with a mature temperature control table, which is easy to learn.

Intelligent power regulation

According to the set temperature, the heating system intelligently recognizes the output power and the output is stable.

| Model | WL6560-2 | |

| Size | The whole machine | 1800mm*952mm*902mm |

| Power control box | 195 mm*150 mm*140mm | |

| Heating Zone | 720 mm*60mm (optional: 80mm, 120mm, 160mm)*70mm | |

| Heating plate | Heating plate name | Ceramic heating plate |

| Number of heating plates | Standard 6 (optional 3, 9, 12) | |

| Single heating plate power | 1000W | |

Delivery | Conveyor belt material | Teflon |

| Transfer speed | 0.5~5m/min | |

| Single heating plate power | 40W (stepless speed regulation) | |

| Conveyor belt width | 650mm | |

| Power | Power Specifications | Three-phase 380V+PE |

| Power | 13000W | |

| Safety | Safety requirements | Ground wire |